ALP KAUCUK SANAYI VE TICARET A.S.

- Brand: ALP

- Founded in 2008 by a team of professionals with over 20 years experience in the field

- Number of employess: 120

- Serves customers from over 50 countries from its factory in Izmir, Turkey, situated on an area of 10 000 square meters

- Wide range of hydraulic and pneumatic sealing elements for various applications (around 9000 items, and constantly increasing), products of technical rubber, technical plastic

- Own tool workshop using CNC machines

- Own in house mixing laboratory which produces all elastomers used in the production of ALP products: NBR, HNBR, EPDM, FKM

- Most up-do-date machinfacturing technology

- Own testing laboratory and complete quality control--all products are subject to quality testing in every stage of production

- Quality management system according to ISO 9001:2008

2272

products

Products

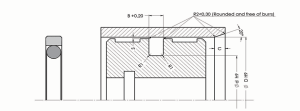

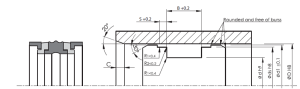

A301 piston seal 14x9.1x2.2 PTFE + bronze + NBR70 up to 400 bar Alp

A301 piston seals are produced by machining technique from a special compound of bronze-filled PTFE, combined with an O-ring used as an energizing ring. A301 can be used safely at high sliding speeds due to its low friction force, which is among one of the essential properties of PTFE. By changing the O-ring material, A301 can be used for type of oils different from mineral-base hydraulic oils.

Material: PTFE + bronze + NBR70

| TECHNICAL DATA | |

| Working pressure | 400 Bar |

| Working temperature | -30/+105°C |

| Sliding speed | 5 m/s |

| Material | PTFE + Bronze / NBR70 |

| Media | Mineral base hydraulic oils |

Manufacturer:

ALP KAUCUK SANAYI VE TICARET A.S.

For delivery options to your country, please do not hesitate to contact us!

In stock 7 pcs.

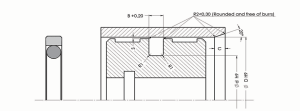

A301 piston seal 12x7.1x2.2 PTFE + bronze + NBR70 up to 400 bar Alp

A301 piston seals are produced by machining technique from a special compound of bronze-filled PTFE, combined with an O-ring used as an energizing ring. A301 can be used safely at high sliding speeds due to its low friction force, which is among one of the essential properties of PTFE. By changing the O-ring material, A301 can be used for type of oils different from mineral-base hydraulic oils.

Material: PTFE + bronze + NBR70

| TECHNICAL DATA | |

| Working pressure | 400 Bar |

| Working temperature | -30/+105°C |

| Sliding speed | 5 m/s |

| Material | PTFE + Bronze / NBR70 |

| Media | Mineral base hydraulic oils |

Manufacturer:

ALP KAUCUK SANAYI VE TICARET A.S.

For delivery options to your country, please do not hesitate to contact us!

In stock 10 pcs.

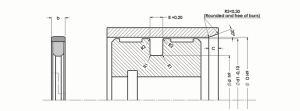

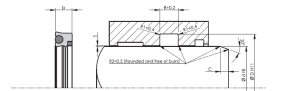

A127-055 heavy duty piston seal with Z-cut 55x44x4.2 NBR80+glass filled PA up tp 800 bar

Double acting heavy duty piston seal type A127 has a Z-cut allowing very easy assembly.

It demonstrates high resistance to hydraulic shock loads and extrusion, very low friction forces, even at the first starting movement in idle hydraulic cylinders in pressurized or non-pressurized environment, excellent static and dynamic sealing properties.

Material: NBR 80/Glass-filled PA

| TECHNICAL DATA | ||

| Working pressure | 800 bar | |

| Working temperature | -30 +105 °C | |

| Sliding speed | 1.0 m/s | |

| Material | NBR 80/Glass-filled PA | |

| Media | Mineral base hydraulic oils | |

| Surface roughness | ||

| Ra | Rmax | |

| Dynamic surface | ≤ 0.2 μm | ≤ 2.0 μm |

| Groove base | ≤ 1.6 μm | ≤ 6.3 μm |

| Groove flanks | ≤ 3.2 μm | ≤ 15 μm |

Manufacturer:

ALP KAUCUK SANAYI VE TICARET A.S.

For delivery options to your country, please do not hesitate to contact us!

In stock 14 pcs.

In stock 18 pcs.

In stock 4 pcs.

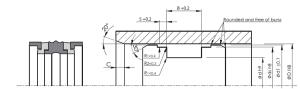

Compact piston seal A105 101.6x127x32.15/6.35 NBR80/TPE/POM+glass filled POM

A105 compact piston seal for hydraulic cylinders consisting of 5 elements - NBR80/TPE/POM + glass filled POM.

In stock 5 pcs.

Compact piston seal A105 101.6x127x32.15 NBR80/TPE/POM+glass filled POM

A105 compact piston seal for hydraulic cylinders consisting of 5 elements - NBR80/TPE/POM + glass filled POM.

In stock 2 pcs.

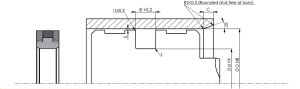

Heavy duty rod seal A152-040 PU 40x52x8.6 PU+POM+NBR

A152 U-ring rod seal has symmetrical lips, an energising O-ring and a POM extrusion ring. It is designed to be used for heavy duty hydraulic cylinders in rod applications. It offers exceptionally high performance in working conditions where high pressure and shock loads are present, provides lower friction, dry rod sealing and increased seal stability of the twin lip design.

A152 can be used safely for construction machinery, moving and loading platforms, forklifts, agricultural machinery, injection moulding equipment, mining and steel industry, and any heavy working condition cylnders, etc.

Its is recommended to be used in combination with minimum one guiding element such as A251, A254, A255, A256, depending on the working conditions.

|

TECHNICAL DATA |

|

|

Working pressure |

600 bar |

|

Working temperature |

-30 +100 °C |

|

Sliding speed |

0.5 m/s |

|

Material |

PU 92 + POM + NBR 70 |

|

Media |

mineral hydraulic oils |

Sizes produced: HERE

Manufacturer:

ALP KAUCUK SANAYI VE TICARET A.S.